Measurement Points

This enables enterprises to view and record the meter readings against the measure points. The inspectors can observe and record the visual data, and also can access activities and tasks overview.

leverage a comprehensive asset maintenance and maximize productivity

Unplanned downtime affects everyone in an organization. Downtime is costly and lost productivity impacts the revenue. To minimize these risks, companies traditionally turn to legacy maintenance practices. These outdated methods further complicate the maintenance strategy of asset-intensive shop floors.

Enterprises that had been facing operational challenges and poor control over their assets can now have a highly configurable solution with built-in capabilities – all in one place. Mobolutions’ Plant Maintenance 360 is a quick-to-deploy asset maintenance solution that comes with tightly integrated maintenance functionality. We provide mobile-based asset maintenance tools and empower users to easily automate and mobilize the maintenance processes.

For a physical asset to be productive, it should be functioning properly. Maintenance is a necessary part of asset management as it directly affects the. production uptime. Plant Maintenance 360 enables enterprises to optimize their assets, processes, and maintenance technicians. The application is a game-changer for most organizations as it maximizes your maintenance productivity.

The solution conveniently augments your maintenance processes and enhances asset-based operations.

Notifications

A robust notification system empowers users to operate maintenance tasks more effectively with real-time alerts via email and WhatsApp. Notification templates can be preconfigured and triggered directly from anywhere.

These notifications can be managed, viewed, and edited from a centralized repository to provide a holistic view of the work orders being created to drive action. The intuitive on-screen maintenance alerts keep you on top of your maintenance.

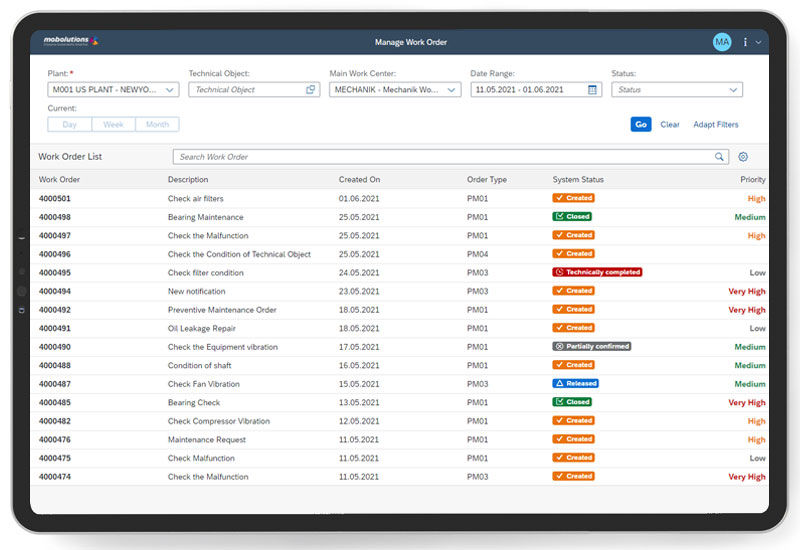

Work Orders

When it comes to Work Order Management, various degrees of outdated systems such as maintenance logs, spreadsheets, and alerting systems are in use.

Create maintenance work orders that contain all the information to initiate and manage maintenance work for an asset. Plant Maintenance 360’s easy-to-navigate app interface helps the users to track the work order status and make faster decisions.

Users can also manage and perform work order activities from the intuitive task pane. You can use filters to search work order details based on the attributes of the maintenance work orders. Track asset service history, event insights, service appointment, and all the needed line item.

Assign Work Orders

Maintenance planners can locate the right technicians, directly assign resources to tasks, and revise resources at any specific time or location. The simple and quick way to schedule and assign work orders standardizes your maintenance workflow.

Time Entry

Efficiently run a complete time-entry against each work orders accurately to calculate the labor rate and costs. This optimized solution facilitates real-time reporting and accurate billable hours.

Create & Approve PR

Plan the purchases of maintenance materials better and optimize organizational spending with streamlined PR creation. It optimizes the procurement initiation and transaction flow by reducing the time and effort to chase paperwork.

As Purchase Requisitions are routed to the authorized approver, The approver will be made aware of this requisition by a workflow message and he/she can view and approve. The approval console is designed in such a way so that the PR can be directed to multiple managers for approval.

Create & Approve PO

Create instant purchase orders from approved purchase requisition, verify purchase order content, and adhere to the compliance efficiently. It is easier to track vendors, handle multiple purchases, inventory, and accounting.

The system sets up an efficient purchase order approval process that minimizes the approval cycle time. Users can manage the complexity of approving different purchase categories and review how the purchase order approval document travels throughout your organization.

Goods Receipts

Create digital records of the inbound movement of goods or materials into the warehouse with the streamlined app. You can enter, view, and edit receipt of material – no matter the variety and quantity of the goods.

This enables enterprises to view and record the meter readings against the measure points. The inspectors can observe and record the visual data, and also can access activities and tasks overview.

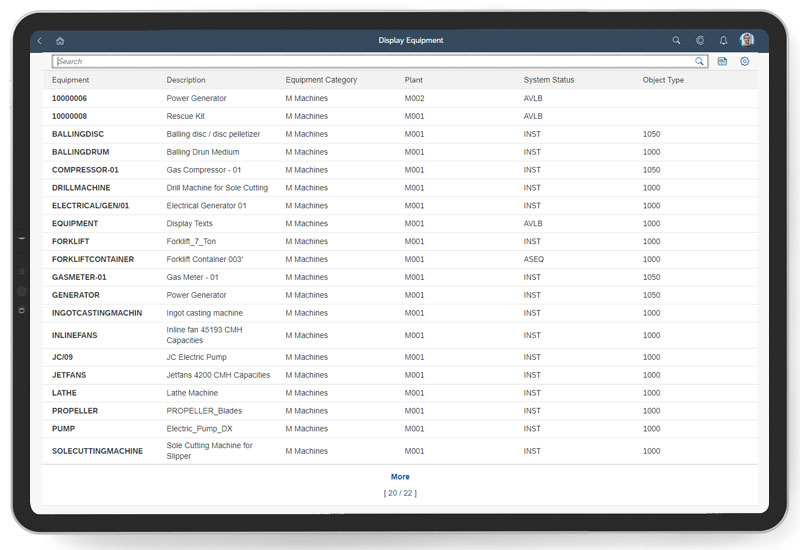

Access the equipment records to perform specialized maintenance on individual machinery. Users can also track the master records centrally on equipment installed at different functional locations.

A functional location represents the place at which a maintenance task is performed. Businesses can have reports on the execution and recordings of maintenance tasks, cost monitoring, and data collection over long periods of time.

Real-time reporting important to optimize maintenance intervals, uncover root causes, decide corrective action plans.

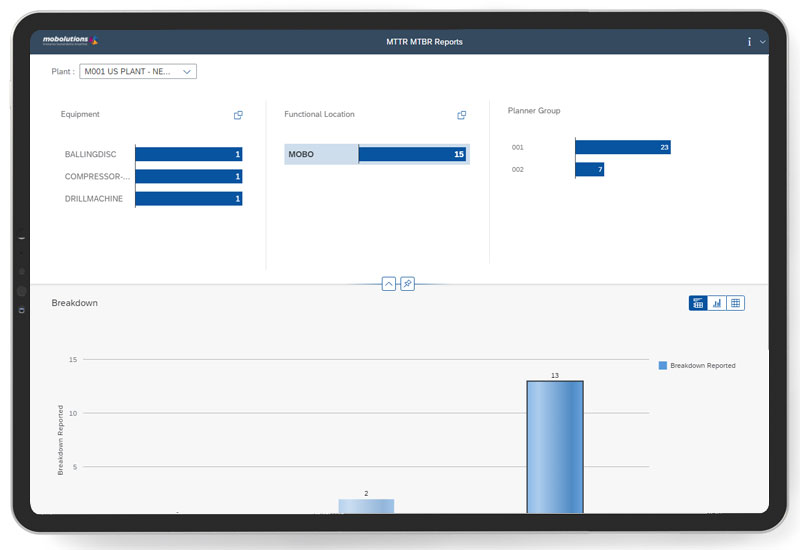

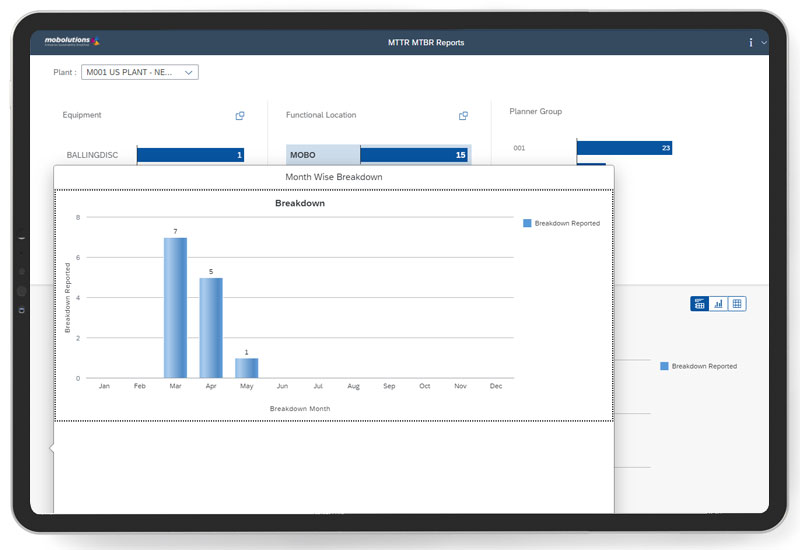

MTTR

Pull up real-time and instant Mean Time To Repair (MTTR) metrics to calculate the time to replace a failed hardware module. It helps to identify the amount of time it took to repair a machine and restore it to full functionality.

MTBR

Track the operating reliability of assets with the most common measure of Mean Time To Repair (MTBR). It is the time elapsed between the required repairs for a particular piece of machinery.

Work Order List

The work order list, by enabling the users to view the past work orders that have been completed, serves as an audit for the number of completed work orders. Users can also accurately track who completed the maintenance, the cost incurred, and the time it took to complete.

Display Equipment

By keeping track of all your inventory on an itemized list, the inventory list allows enterprises to know what they have and what needs to be procured to perform unhindered maintenance. The real-time inventory list helps businesses make informed choices to reduce order amounts.

Manage notifications, work orders, and timesheets using chatbot from any device. Access real-time information about maintenance activities, generate and push notifications instantly to stakeholders without any productivity disruptions. The chatbot can be configured in different channels including WhatsApp, Microsoft teams, and such.

Equipment comes with encoded data that requires a detector for scanning. These details may include information such as geographical codes, web addresses, commercial codes, etc. which are crucial for maintenance. Retrieve the encoded data using the advanced barcode scanner, by first capturing the image of the equipment and then grasping the required information. It scans the equipment based on the operating system of the native device used.

Integrate your Plant Maintenance 360 with the latest advanced technologies like IoT and SCADA that deliver sensor-based data collection and notification triggers. It is achieved through analyzing threshold limits and tracking equipment health analytics. With this integration, preventive and predictive maintenance can be carried out more effectively.

Display information regarding the equipment, functional location, measuring points, and equipment Bills of Materials (BOM) using the Master Data. These details can be visualized as filtered instructions and in the hierarchy view. The retrieved information can also be downloaded as an attachment for further utilization

Get on with the Esri aided GIS software and Geo Map to map your work orders and notifications as pointers based on coordinates. This will help you determine the directions to track assets, resources and view functional locations. Initiate notifications on assignments of job orders to technicians, view technical objects on the map, find out its location, and ETA along with live traffic.

Continue working on creating and managing notifications, work orders, and timesheets even when the network is lost. The offline functionalities let you perform the plant maintenance activities when the native device is offline. This feature results in the improved reliability of PM-360 in all network and non-network environments.

Mobolutions helped us with finance services under Subscription Billing and Services. We have now attained a seamless approach to managing our finances for our contracts. Thanks to Mobolutions for making this journey effortless for us!